A well-designed battery management system BMS ensures safety and reliability in any battery-powered application.Mingtang explores its functional roles and structural designs.

Learn more

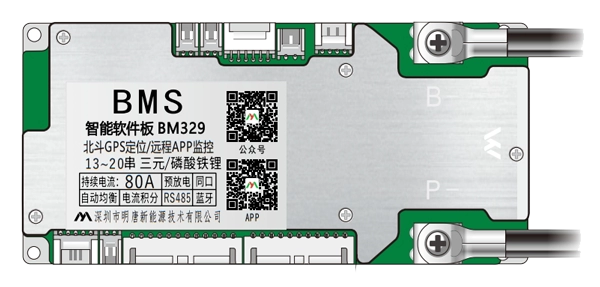

Lithium-ion batteries are now the dominant energy storage technology across industries such as electric vehicles, renewable energy systems, industrial backup, and consumer electronics. However, the true performance and safety of these batteries depend heavily on the supporting Battery Management System (BMS). For engineers, integrators, and procurement managers, understanding the specifications and selection criteria for a BMS for lithium ion battery is critical to ensuring safe and reliable operation. This article Mingtang provides an in-depth look at technical parameters and design considerations for BMS integration. It serves as a comprehensive resource for decision-makers tasked with sourcing and implementing high-quality BMS solutions.

When evaluating a BMS for lithium ion battery, careful attention to its technical specifications is critical. These specifications define how well the system can monitor, control, and protect the battery pack under real-world conditions. Selecting the correct BMS is not simply a matter of matching voltage—it involves ensuring compatibility across electrical, thermal, and communication dimensions.

A well-chosen BMS for lithium ion battery must align with the pack's voltage range, current rating, cell configuration, balancing method, communication interface, and protection level. Each of these parameters determines whether the BMS can deliver accurate measurements, reliable protection, and long-term stability under varying operational environments.

For instance, electric vehicle (EV) applications often demand high-voltage BMS systems capable of managing hundreds of cells in series, while residential or commercial energy storage systems (ESS) may focus on high current ratings and robust communication protocols for integration with energy management systems (EMS). In contrast, compact consumer devices require low-voltage, lightweight BMS units with basic balancing and safety features for cost efficiency.

Moreover, industrial-grade BMS for lithium ion battery solutions are typically designed to function in extreme temperature environments, maintaining accuracy and reliability even under heavy load or harsh conditions. By comparing these specifications to the intended application, users can select a system that delivers optimal safety, performance, and lifecycle value.

| Parameter | Typical Values / Options | Notes |

|---|---|---|

| Voltage Range | 12V, 24V, 48V, 72V, 96V, up to 800V+ | Must match battery pack configuration to ensure compatibility |

| Cell Configuration | 3S–20S (small packs), 100S+ (EV/ESS) | Defines the scalability and capacity of the BMS for lithium ion battery |

| Current Rating | 10A–500A+ | Ensures the BMS can handle charging/discharging loads without overheating |

| Balancing Type | Passive or Active | Passive for cost efficiency, active for high-accuracy energy transfer |

| Communication | CAN bus, RS485, UART, Modbus, Bluetooth | Enables real-time integration with host systems, dashboards, or cloud platforms |

| Protection Features | Over-voltage, under-voltage, over-current, short circuit, over-temperature | Critical for maintaining operational safety |

| Operating Temperature | -20°C to +70°C (standard), -40°C to +85°C (industrial grade) | Defines environmental adaptability and thermal endurance |

| Accuracy | Voltage ±10mV, Current ±1%, SOC ±5% | Determines the reliability of monitoring and control precision |

By carefully matching these parameters to the battery pack design, operating environment, and system requirements, buyers can ensure the chosen BMS for lithium ion battery performs reliably and efficiently. This alignment not only prevents mismatched configurations that could lead to system instability, but also maximizes energy utilization, extends battery life, and enhances overall safety.

Selecting the right BMS for lithium ion battery is a crucial step in ensuring that your energy storage system operates safely, efficiently, and reliably. A well-matched BMS not only protects the cells from electrical and thermal risks but also enhances energy utilization, extends battery life, and ensures compliance with international safety standards.

Because lithium-ion batteries are used across diverse applications—from electric vehicles (EVs) and renewable energy storage systems (ESS) to industrial power units and consumer electronics—the requirements for each application can differ dramatically. Therefore, choosing the correct BMS for lithium ion battery involves evaluating technical, environmental, and functional parameters in line with your project's goals.

Below are the key factors and best practices to consider when selecting the most suitable BMS solution.

The first step in choosing a BMS for lithium ion battery is to clearly define your application's requirements. Different industries have different performance priorities, so understanding your use case ensures you select a BMS that aligns with operational demands:

Electric Vehicles (EVs): Require high-voltage BMS (up to 800V+) with active balancing, CAN bus communication, and advanced thermal management. These features ensure rapid charging, balanced energy distribution, and long-term durability under dynamic load conditions.

Energy Storage Systems (ESS): Need high-capacity BMS for lithium ion battery with large current ratings, multi-layer protection, and remote monitoring capabilities for integration with smart grid or EMS platforms.

Consumer Electronics: Typically use compact, low-voltage BMS solutions with passive balancing and Bluetooth or UART communication for cost efficiency and user safety.

Industrial Power Systems: Demand rugged, industrial-grade BMS capable of operating in harsh environments with high vibration, humidity, or temperature variations.

By clarifying the environment, performance expectations, and operational conditions, you can narrow down suitable models and prevent costly mismatches.

A BMS for lithium ion battery must be compatible with the voltage and current characteristics of the battery pack.

Voltage Range: The BMS should match the nominal voltage of the pack and have appropriate over-voltage/under-voltage thresholds.

Current Rating: It must handle peak charging and discharging currents without triggering false protection or overheating.

Selecting a BMS with insufficient voltage or current capacity can cause incomplete protection, erratic behavior, or even system failure. Conversely, over-specifying can lead to unnecessary cost. Always match the BMS's electrical specifications with the battery configuration and load profile.

The balancing method plays a critical role in maintaining long-term pack health. A well-designed BMS for lithium ion battery typically supports one of two balancing strategies:

Passive Balancing: Dissipates excess energy from higher-voltage cells through resistors. It's simple, cost-effective, and well-suited for small to medium battery packs, such as in consumer electronics or low-voltage energy storage.

Active Balancing: Transfers charge between cells to achieve uniform voltage levels, significantly improving energy efficiency and cycle life. Ideal for EVs, ESS, and industrial systems, where longevity and precision matter.

For high-performance systems, active balancing can deliver up to 10–15% more usable capacity compared to passive designs.

Modern applications demand smart connectivity. A BMS for lithium ion battery should include communication interfaces that enable seamless data exchange with external controllers, monitoring software, or cloud platforms.

CAN bus / RS485: Standard protocols for EV and industrial systems, ensuring fast, reliable communication with vehicle control units or EMS platforms.

Modbus / UART: Common in stationary systems or lower-cost designs for basic data exchange.

Bluetooth / Wi-Fi: Useful for consumer products or portable applications, offering easy access to real-time battery data through mobile apps.

Choosing the correct protocol ensures the BMS integrates smoothly into your overall system architecture, supporting remote diagnostics, firmware updates, and predictive maintenance.

Safety should never be compromised when selecting a BMS for lithium ion battery. Look for models that comply with international certifications and standards, such as:

UL 1973 / UL 2580: For stationary energy storage and EV battery safety.

CE / RoHS: For compliance in European markets.

ISO 26262: For automotive functional safety.

IEC 62619 / IEC 61508: For industrial and ESS applications.

Certified BMS units have undergone rigorous testing to ensure electrical isolation, thermal resilience, fault protection, and long-term reliability. Compliance not only guarantees safety but also facilitates global market access and regulatory approval.

For large-scale deployments—such as commercial ESS or fleet EVs—a modular BMS for lithium ion battery offers greater flexibility.

Modular BMS architectures allow multiple boards or controllers to be connected in parallel or series, enabling:

•Scalable capacity expansion without redesigning the entire control system.

•Simplified maintenance through modular replacement.

•Centralized monitoring across distributed battery units.

This approach future-proofs your investment, ensuring the system can evolve with growing energy demands or new pack configurations.

A frequently overlooked factor in BMS selection is technical support and software ecosystem. A reputable BMS for lithium ion battery supplier should provide:

•Configuration software for parameter tuning and calibration.

•Diagnostic tools for monitoring and troubleshooting.

•Firmware upgrade options for long-term functionality improvement.

•Engineering support to assist with system integration.

This level of service is vital for reducing commissioning time and ensuring stable operation post-installation.

Selecting and procuring the right BMS for lithium ion battery is a multi-step process that requires technical, commercial, and logistical considerations. By evaluating specifications such as voltage range, current handling, balancing method, and communication protocols, engineers ensure compatibility with their battery systems. On the procurement side, assessing supplier reliability, certifications, and support services ensures consistent quality and smooth supply chains. A carefully chosen and properly sourced BMS not only enhances the safety and performance of lithium-ion batteries but also maximizes return on investment through longer lifespan and reduced maintenance costs. For global buyers, following structured selection and procurement practices is the key to unlocking the full value of lithium-ion battery systems.