A BMS for 2 wheelers plays a central role in shaping this consistency by managing discharge behavior, charge control, and system coordination.

Learn more

As battery systems grow in size and complexity, the need for scalable, reliable, and intelligent battery management solutions has become increasingly important. A modular BMS (Battery Management System) offers a flexible and robust architecture by distributing monitoring, control, and protection functions across multiple coordinated modules rather than relying on a single centralized unit. This modular approach improves system scalability, fault isolation, and maintenance efficiency, while enabling accurate monitoring and real-time protection across diverse battery configurations. By integrating advanced sensing, communication, and control algorithms, a modular BMS plays a critical role in ensuring battery safety, performance optimization, and long-term reliability across modern energy storage applications.

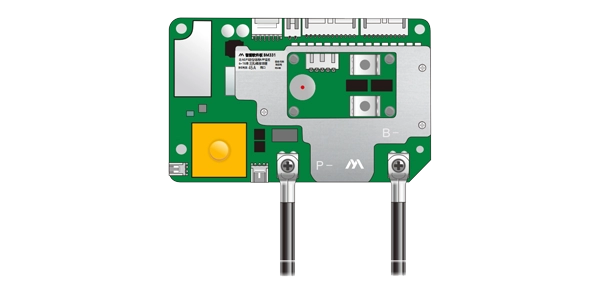

A modular BMS is designed as a distributed and scalable battery management architecture, consisting of multiple coordinated hardware and software units. Instead of relying on a single centralized board, the modular BMS separates monitoring, control, communication, and protection functions into dedicated modules. This architecture enables higher reliability, easier maintenance, and flexible expansion for different battery pack sizes and voltage levels.

At the system level, a modular BMS typically includes a master control unit, multiple slave monitoring modules, robust communication interfaces, and layered protection circuitry. These components work together to ensure accurate sensing, intelligent decision-making, and safe battery operation under varying load and environmental conditions.

The master control unit serves as the “brain” of the modular BMS, responsible for system-wide coordination and high-level decision-making. It aggregates data from all slave monitoring modules and transforms raw measurements into actionable control logic.

Key functions of the master unit include processing voltage, temperature, and current data; executing SOC and SOH estimation algorithms; and managing charge–discharge permissions. The master control unit also coordinates system-level protections, such as enabling or disabling contactors, controlling pre-charge circuits, and issuing fault responses when abnormal conditions are detected.

In addition, the master unit of a modular BMS acts as the primary communication gateway. It interfaces with external systems such as PCS (Power Conversion System), chargers, inverters, EMS platforms, and supervisory control units. To support these tasks, the master controller is typically equipped with a high-performance microcontroller or processor capable of handling large data volumes, real-time computation, and multi-protocol communication.

Slave monitoring modules are distributed measurement units within the modular BMS, each responsible for a specific group of battery cells. This distributed design allows the system to scale efficiently as battery capacity and voltage increase.

Each slave module performs high-precision measurement of individual cell voltages and temperatures, often sampling multiple times per second. In addition to monitoring, slave modules detect local abnormalities such as over-voltage, under-voltage, temperature imbalance, or sensor faults. Many modular BMS designs also integrate balancing circuitry directly into the slave modules.

The modular structure allows slave modules to be added or removed based on battery configuration changes. This flexibility makes a modular BMS highly adaptable for applications ranging from small residential energy storage systems to large-scale industrial or grid-level battery installations.

Reliable and low-latency communication is essential for the performance of a modular BMS. Continuous data exchange between slave modules and the master controller ensures accurate system awareness and timely protective actions.

Commonly used communication protocols in modular BMS designs include CAN bus, RS485, Modbus, Ethernet, and proprietary high-speed serial interfaces. These protocols are selected based on system size, electromagnetic environment, data rate requirements, and integration needs.

Industrial-grade communication design ensures high noise immunity, synchronization accuracy, and stable data transmission even in electrically harsh environments. Robust communication is especially critical for large battery packs, where delayed or corrupted data could lead to incorrect control decisions.

Safety and reliability are core design priorities in a modular BMS, and power supply architecture plays a crucial role. Each module typically operates with an independent, isolated power supply to prevent fault propagation between modules.

Galvanic isolation is commonly implemented between high-voltage battery domains and low-voltage control circuits. Additional protection features include reverse polarity protection, overcurrent protection, short-circuit detection, and transient suppression.

This multi-layer power and isolation design ensures that the modular BMS remains operational even when individual modules experience faults, significantly enhancing overall system stability and safety.

The operational workflow of a modular BMS is based on continuous sensing, real-time analysis, and adaptive control. By combining distributed measurements with centralized intelligence, the system maintains safe and efficient battery operation across all operating states.

Each slave module in a modular BMS continuously monitors individual cell voltages and temperatures at high sampling rates. This real-time data enables the system to track operating conditions with high resolution and accuracy.

The modular BMS uses this information to maintain cells within safe voltage and temperature limits, detect abnormal thermal behavior, and identify weak or aging cells at an early stage. Continuous monitoring allows preventive actions to be taken before faults escalate into critical failures, improving both safety and reliability.

Cell balancing is a fundamental function of any modular BMS, ensuring uniform charge distribution across all cells in the battery pack. Imbalanced cells can reduce usable capacity and accelerate aging.

Modular BMS designs typically support either passive balancing, where excess energy is dissipated as heat, or active balancing, where energy is transferred between cells. Active balancing offers higher efficiency and is often preferred in high-capacity or long-life applications.

Effective balancing improves overall energy utilization, enhances system consistency, and significantly extends battery service life.

Accurate estimation of State of Charge (SOC) and State of Health (SOH) is critical for intelligent energy management. A modular BMS employs advanced algorithms such as coulomb counting, open-circuit voltage analysis, model-based estimation, and temperature-compensated correction methods.

By combining real-time measurements with historical data, the modular BMS can accurately predict remaining energy, assess degradation trends, and estimate remaining useful life. These capabilities are essential for system optimization, predictive maintenance, and long-term reliability.

Protection functions are a core responsibility of a modular BMS. The system continuously evaluates operating conditions to guard against over-voltage, under-voltage, over-temperature, over-current, short circuits, and reverse connections.

When a risk is detected, the modular BMS can immediately trigger protective actions such as relay cut-off, charger shutdown, load disconnection, or alarm notification. Fast and reliable protection mechanisms ensure that the battery system always operates within defined safety boundaries.

Designing a modular BMS requires careful coordination between sensing accuracy, thermal management, and electromagnetic compatibility. Hardware reliability directly affects system safety and lifespan.

Accurate voltage sensing is essential for reliable battery control. Modular BMS hardware typically incorporates high-resolution ADCs, low-noise differential input channels, and temperature-compensated measurement circuits.

These design choices ensure stable and precise measurements even under fluctuating temperatures, load changes, and electrical noise, enabling accurate SOC estimation and effective protection.

Thermal management is a key consideration in modular BMS design. Battery packs generate heat during charging, discharging, and balancing processes, and excessive temperature can accelerate degradation.

To address this, modular BMS designs include optimized PCB layouts for heat distribution, strategically placed temperature sensors, heat-resistant materials, and thermal protection strategies. These measures help maintain safe operating temperatures and consistent system performance.

In high-power battery systems, electromagnetic interference can affect measurement accuracy and communication stability. A modular BMS incorporates EMI mitigation techniques such as shielding, grounding layers, filtering circuits, and high-quality connectors.

Effective EMI control ensures reliable operation in environments with strong electrical noise, such as industrial plants, renewable energy systems, and electric vehicle platforms.

Software intelligence is what transforms hardware measurements into meaningful control actions. In a modular BMS, software plays a central role in data processing, diagnostics, and system coordination.

The master controller of a modular BMS continuously processes voltage, temperature, current, and historical data from all modules. Based on this information, it executes balancing strategies, issues protective commands, and manages communication with external systems.

Real-time processing ensures fast response to changing operating conditions and supports stable battery performance.

Advanced fault diagnosis algorithms enable a modular BMS to detect degraded cells, abnormal temperature patterns, sudden voltage drops, and intermittent communication errors. Long-term data analysis also supports aging assessment and predictive maintenance.

These diagnostic capabilities help reduce unplanned downtime and improve overall system reliability.

A modular BMS records critical operational data for performance analysis, fault tracing, and compliance reporting. Logged data can be transmitted to remote monitoring platforms, cloud systems, or industrial servers.

Comprehensive data logging enhances transparency, supports system optimization, and simplifies maintenance planning.

A modular BMS is an indispensable component for any scalable and high-performance battery system. Its flexible design, advanced monitoring capabilities, intelligent control algorithms, and robust hardware architecture ensure safe and efficient battery operation across a wide range of industries. Whether used in renewable energy storage, electric vehicles, telecom backup, or industrial equipment, a modular BMS delivers reliability, efficiency, and long-term value.