A modular BMS is an indispensable component for any scalable and high-performance battery system.

Learn more

In the commercial transportation industry, consistent engine performance is non-negotiable. Whether delivering goods cross-country or operating on construction sites, trucks rely heavily on efficient and stable power management systems. A truck start BMS (Battery Management System) plays a vital role in ensuring that the truck starts reliably under all conditions. Unlike standard battery systems, a truck start BMS is engineered to handle high-current discharge, extreme environments, and the demanding requirements of commercial vehicles. This article Mingtang explores the key functionalities of a truck start BMS. Whether you're a fleet manager, procurement officer, or technical consultant, understanding this system is crucial to optimizing performance and avoiding costly downtimes.

A truck start BMS is a specialized battery management system designed specifically for starting truck engines and maintaining the performance of starter batteries. It manages the charging, discharging, protection, balancing, and communication of the battery pack, ensuring that the battery operates safely and efficiently. The system is typically used in 12V or 24V lithium-ion starter battery configurations, though it can be adapted for other voltages depending on the vehicle design. Unlike energy storage BMS solutions that focus on long-term capacity management, the truck start BMS is optimized for short-term high-current output, fast recovery, and immediate voltage stability.

A truck start BMS (Battery Management System) is the nerve center of a lithium-ion battery system designed for heavy-duty vehicle engine starts. Far more advanced than standard BMS units found in consumer electronics or stationary storage systems, the truck start BMS must respond to extreme power demands, harsh environmental conditions, and safety-critical operational scenarios.

Here are the core functional areas where a truck start BMS plays a pivotal role in ensuring performance, protection, and long-term system reliability.

Starting a large diesel truck engine requires massive bursts of electrical current—often hundreds or even thousands of amps in a split second. A high-quality truck start BMS is engineered to handle these intense discharge rates without compromising safety or component integrity.

To achieve this, the system incorporates:

Precision current sensors capable of detecting rapid changes in current draw.

MOSFETs or relays that can quickly activate or isolate power pathways.

Thermal compensation algorithms to prevent overheating during prolonged or repeated cranking cycles.

Without effective high-current discharge management, battery cells could experience voltage sag, internal damage, or even catastrophic failure. The truck start BMS ensures the battery delivers consistent power when it matters most—during cold starts, rapid restarts, or extended cranking events.

Heavy-duty starting systems are prone to electrical hazards such as cable faults, terminal shorts, or sudden load anomalies. A well-designed truck start BMS continuously monitors all current pathways and reacts instantly when it detects unsafe spikes or short-circuit conditions.

Within milliseconds, the BMS can:

Interrupt the power flow using solid-state switches or mechanical contactors.

Log the fault event for later diagnostics.

Isolate the affected segment to prevent escalation.

This proactive protection prevents dangerous outcomes like thermal runaway, component burnout, or battery pack fire, all of which are significant risks in high-power applications. By providing this level of real-time current protection, the truck start BMS safeguards both the electrical system and the vehicle itself.

Starting engines in cold climates presents unique challenges. Lithium batteries typically suffer from reduced performance at low temperatures due to slowed ion mobility. A specialized truck start BMS addresses this with integrated thermal management features, including:

Preheating circuits that warm battery cells to optimal operating temperature.

Temperature sensors placed throughout the battery pack for precise environmental monitoring.

Intelligent start logic that delays or modulates discharge until safe conditions are reached.

These features allow the truck start BMS to enable reliable cold-weather ignition, even in sub-zero conditions that would normally render a battery inoperative. This is especially critical for logistics fleets, emergency vehicles, and off-road machinery that must perform in any environment.

Lithium battery packs are composed of multiple cells connected in series and parallel. Over time, differences in charge/discharge rates, temperature exposure, and manufacturing tolerances can cause these cells to become imbalanced. A truck start BMS performs active or passive voltage balancing to ensure that each cell maintains optimal voltage levels.

Key features include:

Cell-by-cell voltage monitoring, detecting imbalances as small as a few millivolts.

Balancing circuits that bleed or redistribute energy to correct imbalances.

Fault isolation, allowing the system to ignore or flag defective cells without shutting down the entire battery.

Maintaining voltage uniformity not only improves overall pack performance and capacity, but also extends the usable life of the battery. A well-balanced pack is less likely to experience localized stress, swelling, or premature degradation—making voltage balancing a critical function of any professional-grade truck start BMS.

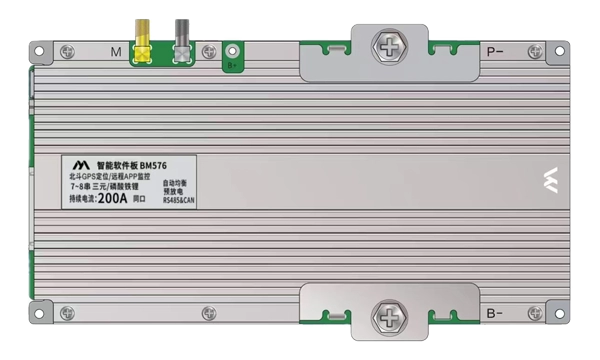

Modern commercial vehicles are increasingly connected, and so are their energy systems. A truck start BMS supports real-time data communication via CAN bus (Controller Area Network), allowing seamless integration with the vehicle's ECU and telematics platforms.

This enables:

Live monitoring of battery state-of-charge (SOC), state-of-health (SOH), and temperature.

Fault codes and system alerts to be logged and shared with fleet maintenance systems.

Remote diagnostics, predictive maintenance, and integration with over-the-air (OTA) firmware updates.

With CAN-enabled diagnostics, the truck start BMS becomes a vital part of a data-driven maintenance strategy. Fleet operators can proactively address issues before failures occur, improving uptime and lowering service costs. In safety-critical applications—such as public transportation or emergency response—the added layer of transparency and control provided by real-time diagnostics is invaluable.

For any business that depends on the reliable operation of heavy-duty vehicles, investing in a high-quality truck start BMS is a strategic move. It not only ensures the safe and consistent performance of the truck's battery system but also enhances the overall durability and cost-effectiveness of fleet operations. With the right BMS, you can reduce maintenance costs, prevent unexpected breakdowns, and ensure operational continuity even in the harshest conditions. If you're looking for a supplier of advanced truck start BMS solutions tailored to your fleet, be sure to evaluate technical support, OEM customization, and certification standards. The right partner will deliver not just a product—but a performance guarantee on every start.