In the world of electrification, the battery serves as more than a passive energy source. It functions as an intelligent, managed resource that powers everything from electric vehicles and renewable energy systems to aerospace systems and high-performance industrial machinery. At the center of this intelligent energy ecosystem is the battery management system BMS. A battery management system (BMS) plays a critical role in ensuring the battery operates within safe, efficient, and optimal parameters. It safeguards the cells, manages charge and discharge cycles, provides real-time diagnostics, and interfaces seamlessly with larger energy management infrastructures. In this comprehensive article, Mingtang delves deep into the professional architecture, performance features, and engineering mechanics of the battery management system BMS, while avoiding any historical overviews or speculative forecasts.

Functional Roles of a Battery Management System BMS

The battery management system BMS is designed to provide a full suite of monitoring, control, and protective features tailored to the battery's specifications and its application. These core roles are essential to maintain performance, extend battery life, and protect surrounding systems. Without a capable BMS, even the most advanced battery chemistry becomes vulnerable to inefficiencies and hazards.

Cell-Level Voltage and Current Regulation

The BMS continuously monitors the voltage of each individual cell within a pack. Maintaining cell voltage within a narrow safe range (typically 2.5V to 4.2V for lithium-ion cells) is essential for avoiding degradation, overcharging, or unsafe discharge conditions. This is especially critical in series-connected battery strings, where imbalance can quickly lead to performance degradation or thermal events. A well-designed battery management system BMS ensures each cell operates harmoniously with the others. The current paths are also managed meticulously. During both charging and discharging cycles, the BMS imposes strict current limits based on cell chemistry and thermal conditions. This prevents excessive heat generation or irreversible internal damage. The battery management system BMS must dynamically regulate current based on real-time data, contributing to both longevity and user safety.

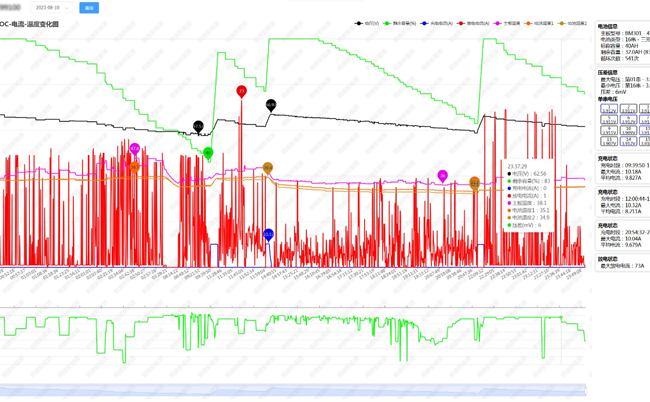

Intelligent Temperature Monitoring and Control

Thermal management is one of the most important tasks of any BMS. Multiple temperature sensors are positioned across the battery pack to monitor temperature gradients. When heat levels exceed predefined thresholds, the BMS responds by limiting power flow, activating cooling fans, or disengaging the system entirely. In some designs, the battery management system BMS integrates with thermal management systems such as liquid cooling loops or Peltier elements to actively manage heat dissipation. By managing temperature intelligently, the BMS prevents both degradation and dangerous scenarios such as thermal runaway.

State of Charge (SOC) Computation

The battery's state of charge (SOC) represents the remaining usable capacity. A BMS computes SOC through a combination of coulomb counting and voltage-based models, often refined with temperature correction and data-driven filtering algorithms. The battery management system BMS ensures accuracy in these computations even under variable load conditions, critical for systems such as EVs or grid storage. Accurate SOC reporting allows users and system controllers to make informed decisions regarding energy availability and system performance. For vehicles, this means more accurate range estimation; for solar storage, smarter grid interaction. Without a reliable battery management system BMS, such estimations become guesswork, risking system failure or inefficiency.

Cell Balancing and Equalization

Over time, inconsistencies in internal resistance and capacity cause imbalances between cells. A well-engineered battery management system BMS detects these differences and actively balances cells, either passively (resistor bleeding) or actively (energy redistribution). Cell balancing is not just about performance; it is about safety and extending system life. Balanced cells enable deeper discharges and more complete charging cycles, leading to enhanced energy utilization and prolonged battery life. The battery management system BMS manages balancing during both operation and idle periods to optimize every cycle of energy storage and release.

Fault Detection and System Protection

From over-voltage and under-voltage events to short circuits, over-temperature excursions, and communication failures, a BMS serves as the central guardian of system integrity. It quickly isolates faults and prevents them from propagating across the system. This proactive fault isolation is one of the most vital functions of a battery management system BMS. In high-risk applications like aerospace or electric transit, the BMS may also activate redundant pathways or initiate controlled shutdown protocols. By doing so, the battery management system BMS ensures the safety of both equipment and users, often acting faster than human reflexes can respond.

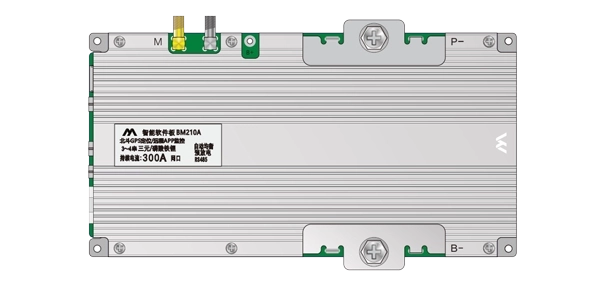

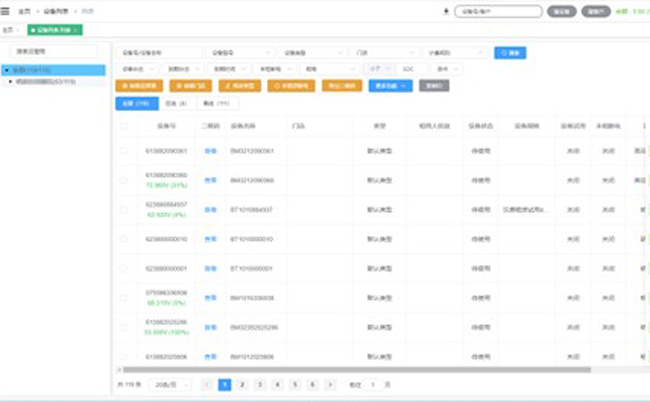

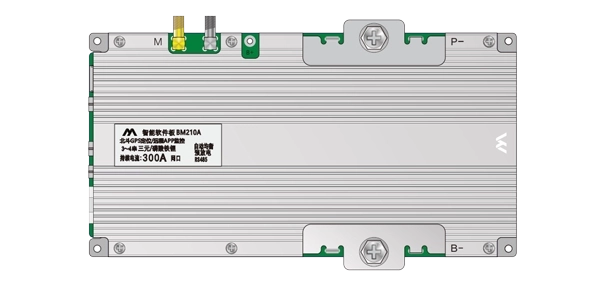

External Communication and Control Integration

Modern BMS units provide data to external systems via communication protocols such as CAN bus, RS-485, or Modbus. These interfaces allow real-time telemetry sharing with vehicle controllers, smart chargers, solar inverters, and energy management systems. The battery management system BMS is often a node in a larger network of control and diagnostic systems. This connectivity empowers distributed energy systems, enabling coordinated charging, diagnostics, firmware updates, and cloud-based analytics. A battery management system BMS with robust communication capabilities is fundamental for modern IoT-enabled energy platforms.

Structural Designs and Deployment Models for Battery Management System BMS

The configuration of a battery management system BMS must align with the electrical architecture and deployment environment. These design choices are central to reliability, modularity, and scalability. Selecting the appropriate topology ensures the system performs optimally in its intended use case.

Centralized BMS Configurations

In centralized BMS architecture, all sensor inputs and control circuitry reside on a single PCB. This layout is suitable for low-voltage packs or compact products where space efficiency and simplicity are critical. A centralized battery management system BMS is easier to design and cost-effective for small-scale applications. While economical and lightweight, centralized systems may suffer from limitations in signal integrity due to the extensive wiring required for high cell counts. Thus, the use of centralized battery management system BMS is generally reserved for limited cell count and low-complexity energy storage units.

Distributed BMS Architectures

Distributed BMS designs divide sensing and control across multiple modules, each managing a subset of cells. These modules relay data to a central controller via a robust communication bus. The battery management system BMS in this architecture is more resilient and allows modular expansion. This layout is ideal for electric vehicles, aircraft, or industrial battery modules, where thermal gradients and spatial considerations favor localized control. A distributed battery management system BMS supports better thermal management and maintenance of signal quality.

Modular BMS (Master-Slave) Systems

Modular BMS topologies use multiple identical modules (slaves), each with full BMS functionality, coordinated by a master unit. This provides redundancy and allows large battery packs to be built from standard sub-units. A modular battery management system BMS also allows for easy servicing and scalability. Such systems are widely used in grid-scale storage and defense sectors, where reliability and upgradability are paramount. The battery management system BMS serves as the orchestrator for the entire energy platform, ensuring all modules operate in harmony.

A well-designed battery management system BMS ensures safety, efficiency, and reliability in any battery-powered application. It monitors critical parameters, balances cells, and protects against faults, enabling batteries to perform at their best. Whether in electric vehicles, renewable energy storage, or industrial systems, the battery management system BMS is an essential component that maximizes performance and extends battery life. Choosing the right BMS is key to building safe and dependable energy systems.